Stacking Magazine Exercises

Learning about components and their functions

Learning objective

Upon completing this exercise, you should be familiar with the most important components used in the stacking magazine station

Problem description

All automated systems use a range of components such as sensors, valves, motors, etc. It is important to be familiar with the function of the components in a system.

Learning objective

Upon completing this exercise, you should be familiar with the most important components used in the stacking magazine station

Problem description

All automated systems use a range of components such as sensors, valves, motors, etc. It is important to be familiar with the function of the components in a system.

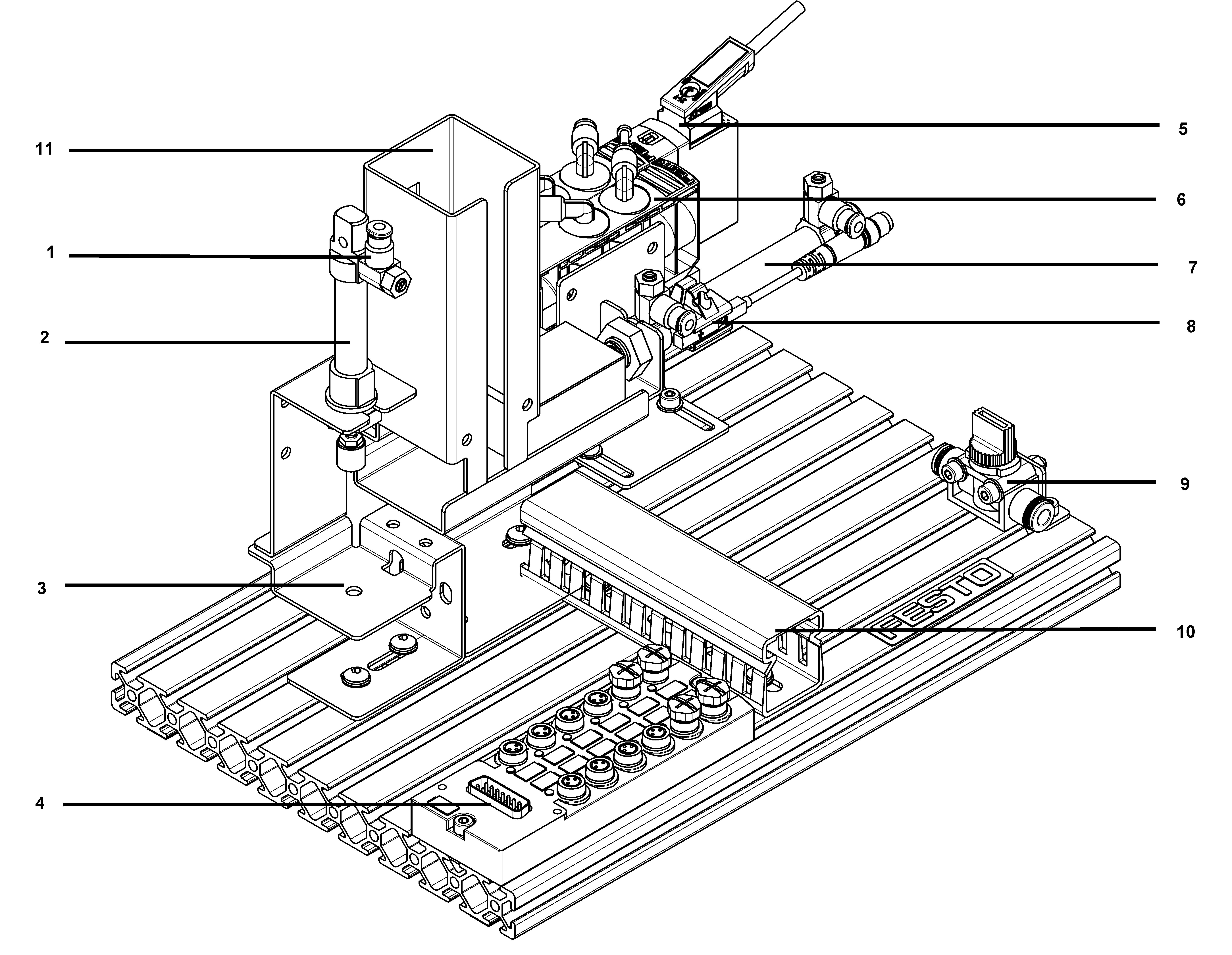

Match the components with their correct designation and describe their purpose within the station.

Function Description

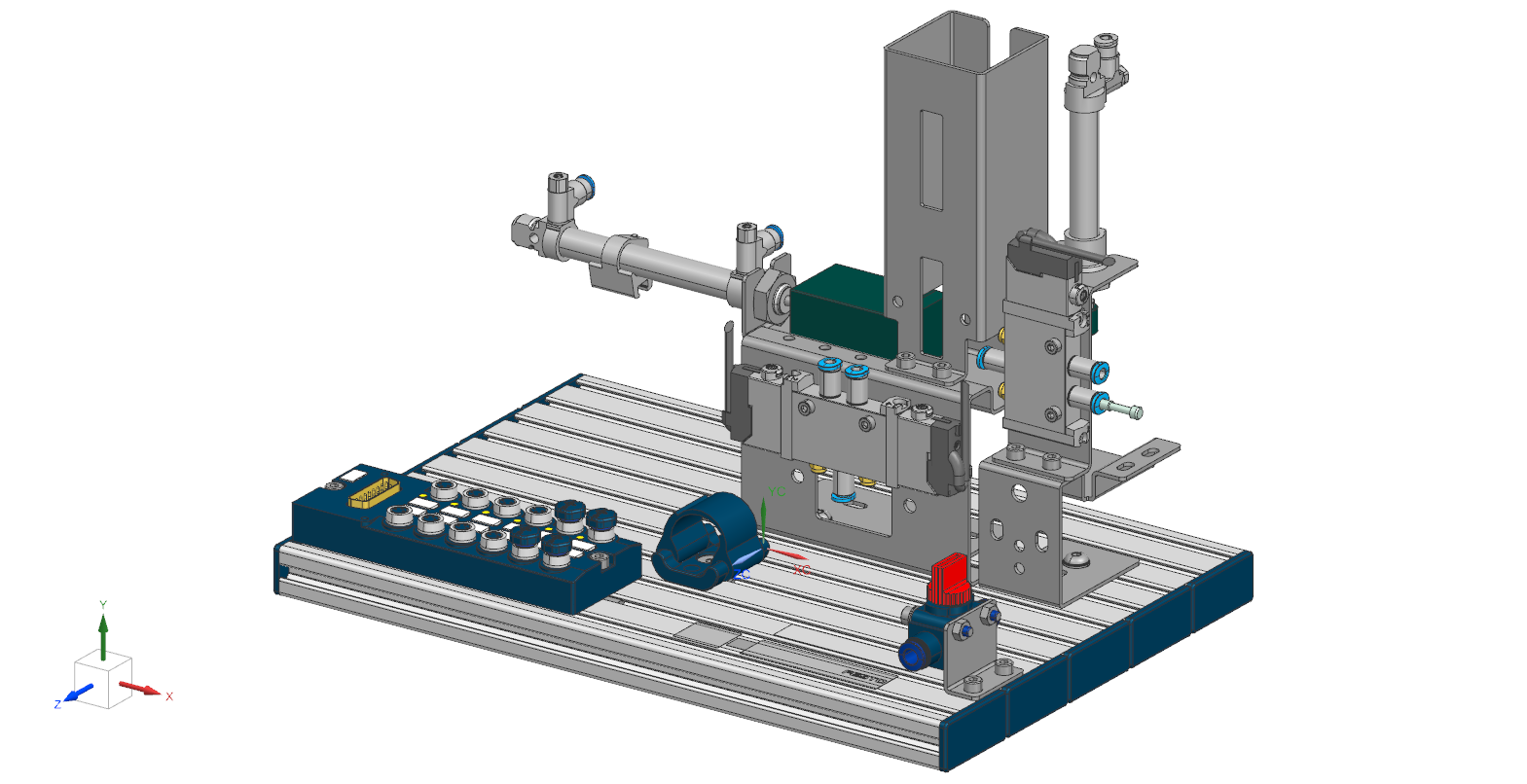

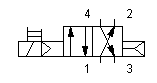

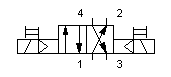

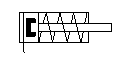

The Stacking Magazine Station holds and stacks a certain quantity of work pieces. The workpieces are stacked on top of each other in the magazine. One by one, a workpiece is pushed out by a double-acting cylinder onto a storage plate. The cylinder is equipped with a magnetic proximity sensor, which detects the piston and outputs a signal. On the storage plate, the work piece is joined with a cover by a single-acting cylinder. After the joining process, a spring pushes the piston back to its upper starting position. In order to regulate the speed of the piston, the single-acting cylinder is equipped with an one-way flow control valve. Both cylinders have to move in a specific order. To realize the correct process sequence, one 4/2-way double solenoid valve actuates the double-acting cylinder and a second 4/2-way single solenoid valve actuates the single-acting cylinder. Both valves are controlled with electric signals. When the valves are activated, they foreword compressed air to the cylinders. The main supply of compressed air can be turned off manually with an 3/2-wayhand valve. Cables for electrical signals can be collected and routed in a cable duct for a neat installation. To distribute enough electrical connections for sensors and actuators, a multi-pin plug distributor is also installed on the baseplate.

No.

Designation

Function within the station

1

2

3

4

5

6

7

8

9

10

11

Learning about components, symbols and designations

Learning objective

Upon completing this exercise, you should be familiar with the symbols and designations of key pneumatic components

Problem description

All automated systems use a range of components such as sensors, valves, motors, etc. It is important to describe the function of the system clearly and simply to all involved. This is done using, among other things, electrical, pneumatic and hydraulic circuit diagrams. To understand these circuit diagrams, you must be familiar with the symbols used.

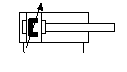

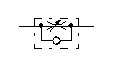

Match the components and symbols with the correct designations. Do this by dragging the designation to the component in the correct fields in the “Designation” columns.

Learning objective

Upon completing this exercise, you should be familiar with the symbols and designations of key pneumatic components

Problem description

All automated systems use a range of components such as sensors, valves, motors, etc. It is important to describe the function of the system clearly and simply to all involved. This is done using, among other things, electrical, pneumatic and hydraulic circuit diagrams. To understand these circuit diagrams, you must be familiar with the symbols used.

Match the components and symbols with the correct designations. Do this by dragging the designation to the component in the correct fields in the “Designation” columns.

Component

Symbol

Designation

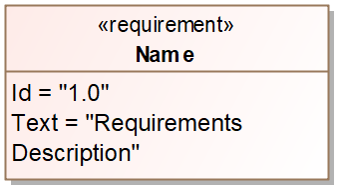

MBSE - Exercise Description

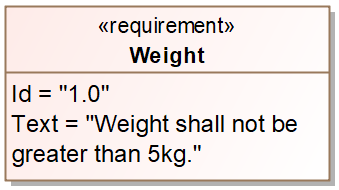

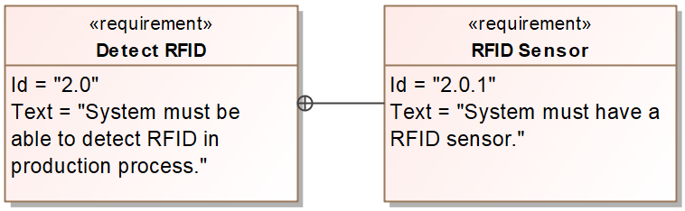

The Stacking Magazine Station can be designed as a (sub-)system of a bigger production line. Systems modelling has increased in importance because of the complexity of modern systems. Model Based Systems Engineering (MBSE) is the computed aided method of conceptualizing and designing such systems. A commonly used description language is the Systems Modelling Language (SysML) which has some similarities to the Unified Modeling Language (UML). A difference between both modeling languages is the capability of SysML to manage requirements. In SysML requirements are treated as objects. In requirements diagrams, different requirements can be connected with relationships. Such relationships allow us to describe and understand where requirements come from and how they belong together. That allows a complex modeling and management of system requirements.

UML

SysML

Name

Symbol

Description

Example

Requirement

Object that represents a necessity

Containment

relation

relation

Describes a „is-part-of“-relationship, similar to Aggregation

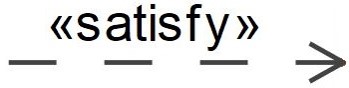

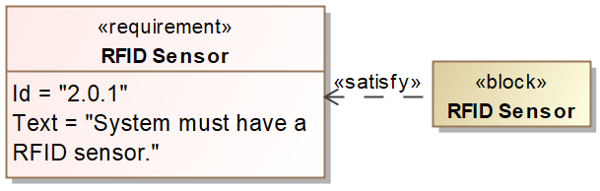

Satisfy

relation

relation

Links requirement to a valid component

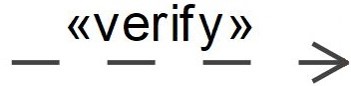

Verify

relation

relation

Links requirement to an activity that actually verifies requirement

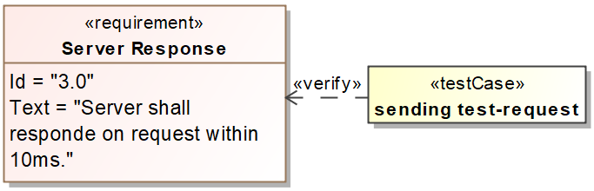

Refine

relation

relation

More detailed description of a requirement

Exercise:

The Stacking Magazine Station is used to stack and hold a defined amount of workpieces so that automatically one by one a single workpiece can be pushed out by a cylinder. Before detailing single components, requirements for the system have to determined by the customer. In the following example, we will focus on functional requirements. Functional Requirements can be divided into Process Requirements and Installation Requirements. The Process Requirements can be divided in five sub-requirements. The customer expects that the joining force of the single-acting cylinder does not exceed 50N. Otherwise, the storage plate can be damaged. Additionally, the capacity of storing workpieces will not be more than 5 pieces. These requirements are satisfied by the component Magazine. In case the single-acting cylinder has to be changed, an easy exchange has to be possible. Because of security reasons, the main supply of compressed air shall be tuned off by hand. A 3/2-way hand valve is a valid component for this task. The customer also wants a fast production process. Therefore, he aspects the cycle time to be less than 10s. You created a test case, which calculates the duration verifies the requirement.

Installation Requirements can be divided in two more sub-requirements. In order to operate the station properly, the multi-pin plug distributer shall have at least 4 plugs for sensors and actuators. In the technical drawing, you can see that the chosen distributer has enough plugs. All cables, that provide an electrical connection for sensors and actuator, shall be collected in a cable duct for a neat installation.

Complete the Requirements-Diagram down below using all elements. Drag and drop requirements, relationships, activities and components in the right place. Hint: First start using the requirements, then add relationships and components.

The Stacking Magazine Station is used to stack and hold a defined amount of workpieces so that automatically one by one a single workpiece can be pushed out by a cylinder. Before detailing single components, requirements for the system have to determined by the customer. In the following example, we will focus on functional requirements. Functional Requirements can be divided into Process Requirements and Installation Requirements. The Process Requirements can be divided in five sub-requirements. The customer expects that the joining force of the single-acting cylinder does not exceed 50N. Otherwise, the storage plate can be damaged. Additionally, the capacity of storing workpieces will not be more than 5 pieces. These requirements are satisfied by the component Magazine. In case the single-acting cylinder has to be changed, an easy exchange has to be possible. Because of security reasons, the main supply of compressed air shall be tuned off by hand. A 3/2-way hand valve is a valid component for this task. The customer also wants a fast production process. Therefore, he aspects the cycle time to be less than 10s. You created a test case, which calculates the duration verifies the requirement.

Installation Requirements can be divided in two more sub-requirements. In order to operate the station properly, the multi-pin plug distributer shall have at least 4 plugs for sensors and actuators. In the technical drawing, you can see that the chosen distributer has enough plugs. All cables, that provide an electrical connection for sensors and actuator, shall be collected in a cable duct for a neat installation.

Complete the Requirements-Diagram down below using all elements. Drag and drop requirements, relationships, activities and components in the right place. Hint: First start using the requirements, then add relationships and components.

Pool of elements and relationships

Inspired by Festo