Industrial Internet Of Things/

Digital Twin Platform

Test on connected production equipment/line in Germany and Asia

Use the Testbed for scalable transformation to global connected production line

Establish a network for IIoT trainings and research

Information -

Storyline

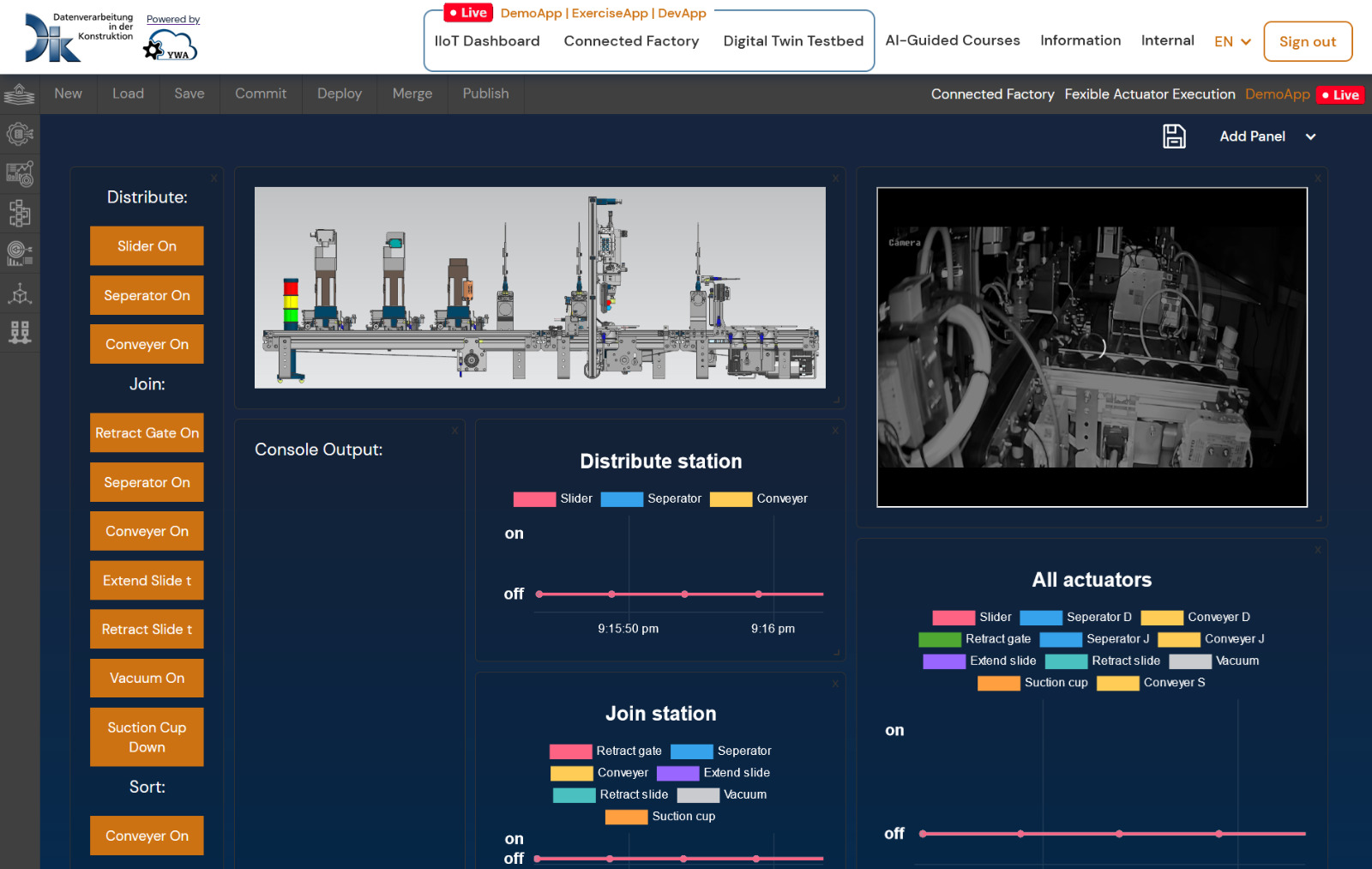

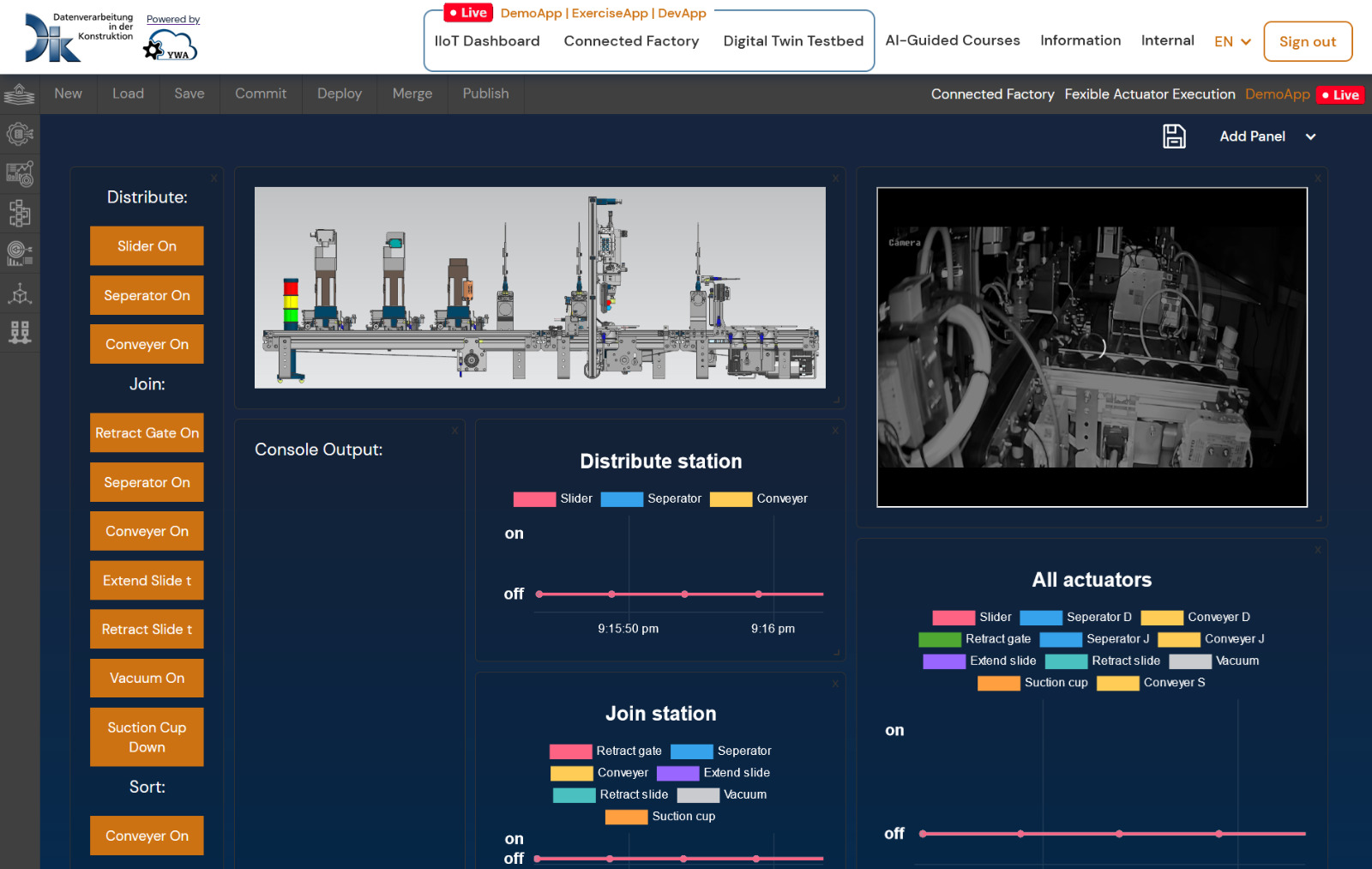

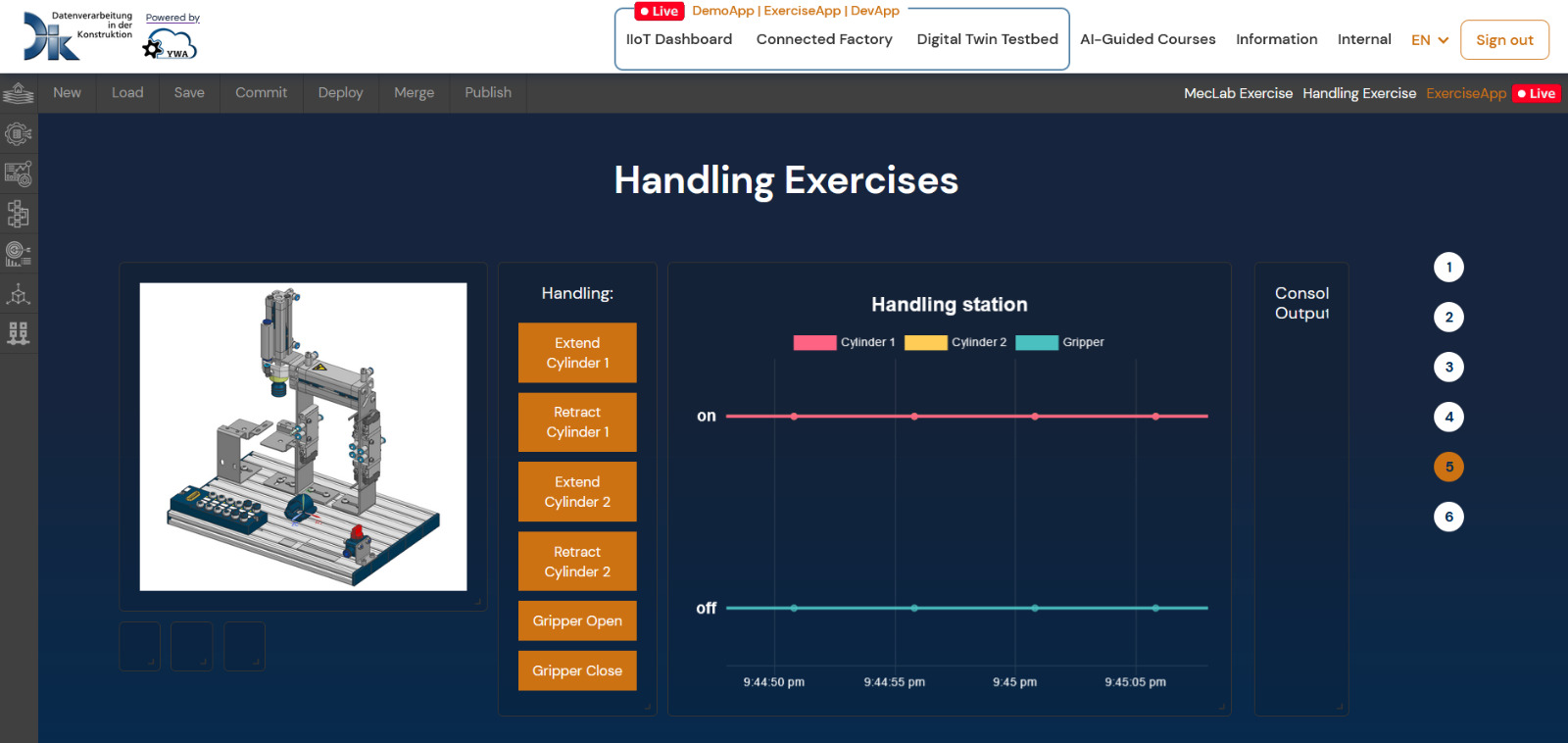

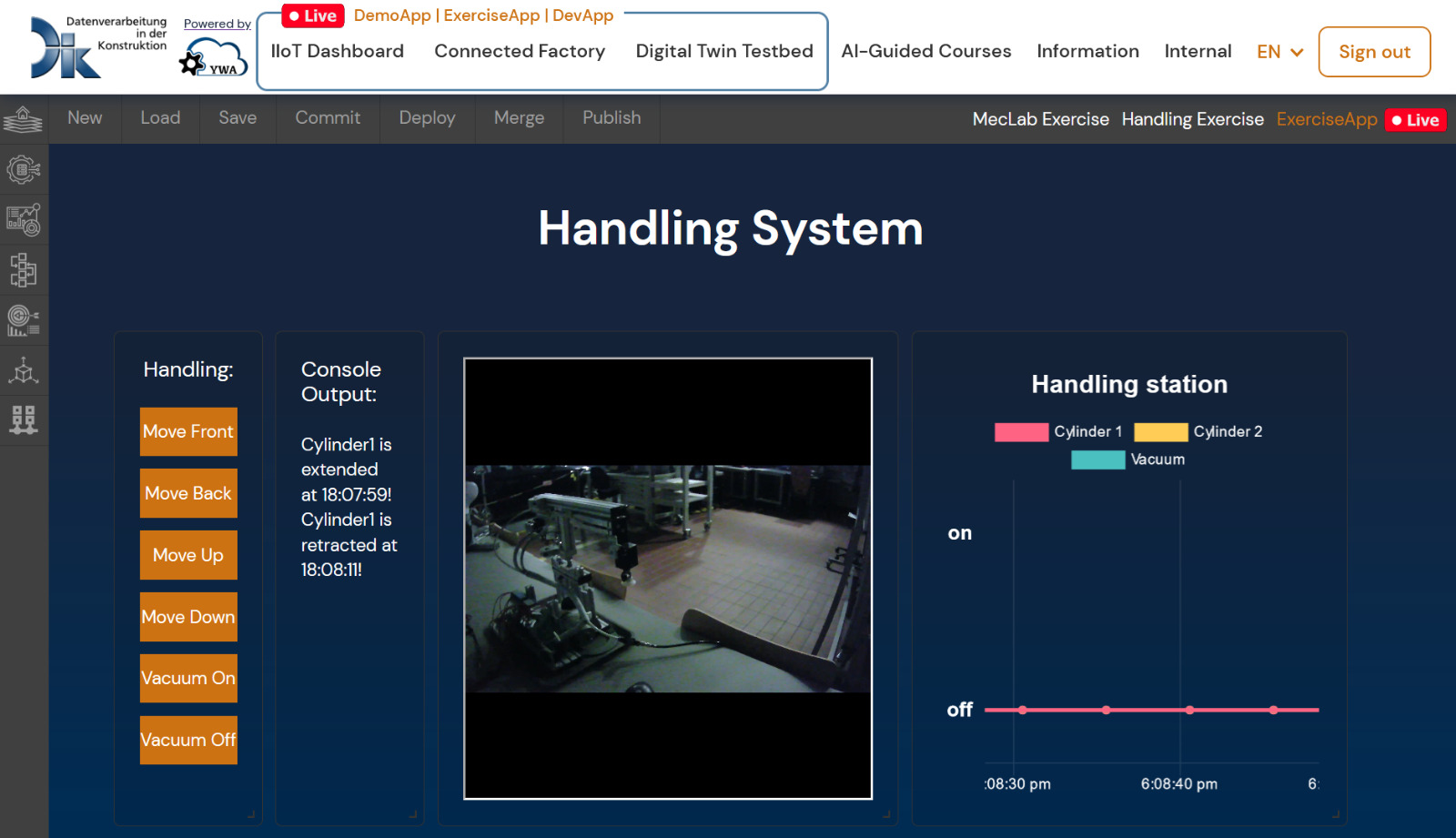

For the public testbed at TU Darmstadt DiK, AI-Dave and AI-Jane established a virtual and physical bidirectional interaction testbed via Amazon Web Services [AWS], Microsoft Azure or Google Cloud through AI-Dave and AI-Jane's "Digital Twin Factory" application. Any client-device (e.g. Holo-Lens 2, HTC Vive Pro, Personal Computer, Tablet, Mobil phone etc.) could connect securely through cloud-server to the public testbed offered industrial machineries (e.g. collaborative robots, industrial production/assembly line etc.). The bidirectional control through AI-Dave and AI-Jane's "Digital Twin Factory" application allows the client-devices to interact with the level of Manufacturing Execution System [MES], the level of Programmable Logic Controller [PLC] as well as the level of any interlinked sensor or actuator.

Additionally, for internal and external models, software or hardware extensions, the developer will be guided interactively through model integration (CAD, FEM, MBS, CFD etc.) as well as data orchestration (REST-architecture for SOA, TCP/IP, OPC UA, MQTT, I/O Level etc.) with the existing Digital Twin Factory architecture.

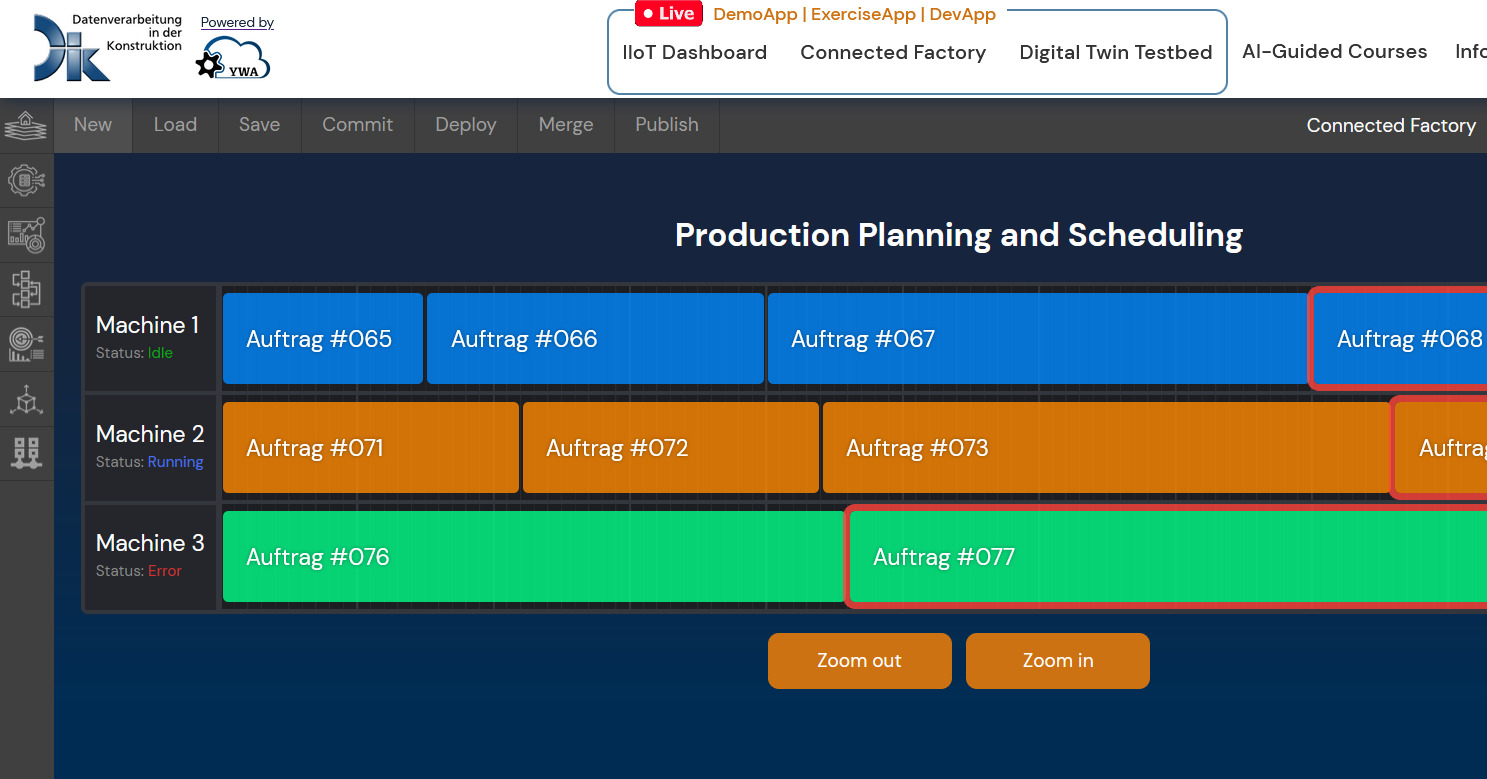

Therefore, use cases like cloud conditioning and order monitoring or cloud dashboard engineering are basic functionalities. Advanced cloud production order and single actuator execution as well as cloud simulation model-based preventive and predictive maintenance are established. Professionally, cloud virtual commissioning and semi-automatic EBOM to MBOM transformation could be developed, tested and operated virtually or physically though public cloud providers e.g. AWS, Azure, Google Cloud etc.. Alternatively, private cloud environment at HRZ-Servers [Hochschulrechenzentrum], TU Darmstadt DiK, Germany could be used. Industrial production equipments were well established and connected for Europe-Asia cross boarder test.

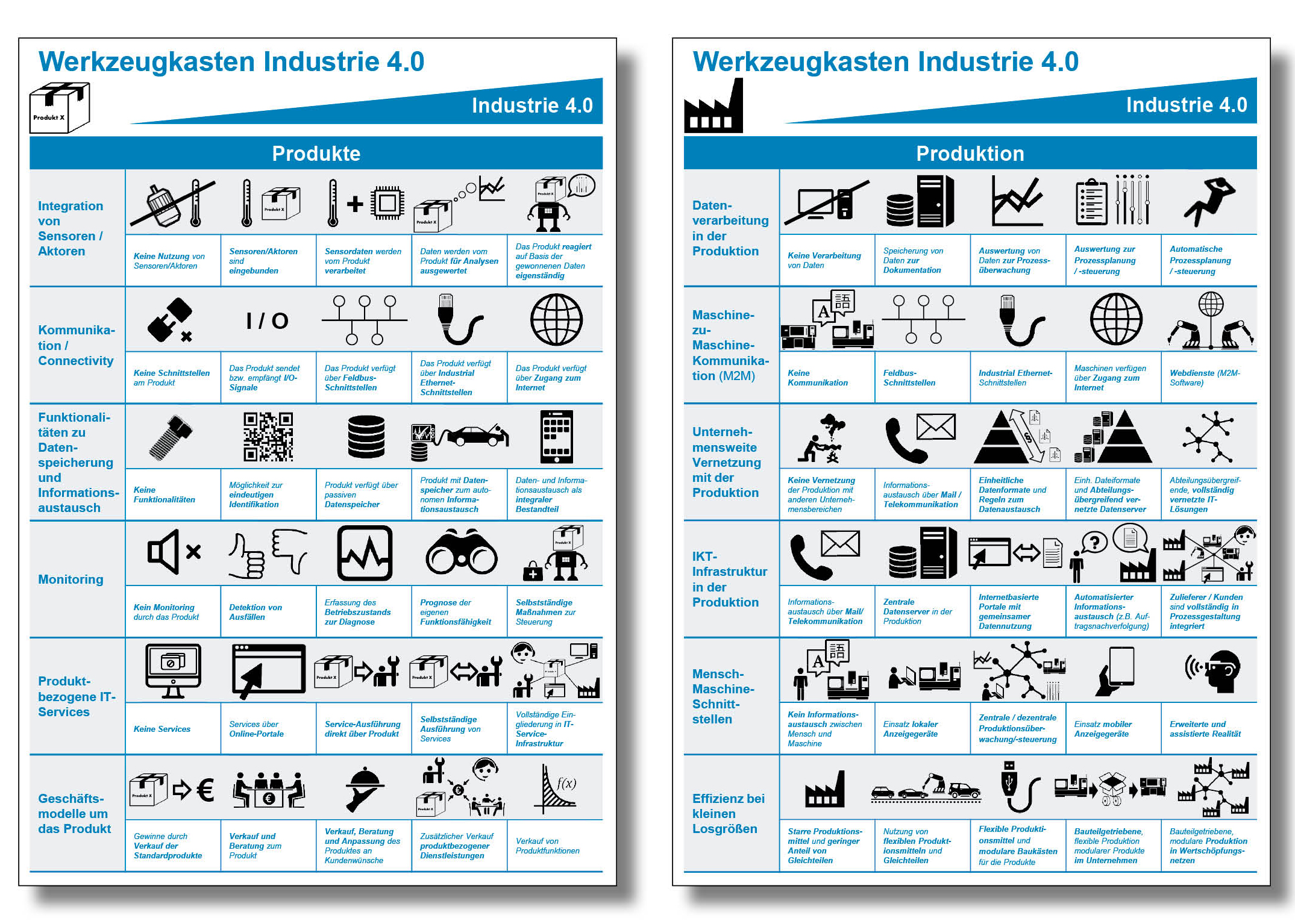

Finally, the provided use cases and benefits for enterprise are methodologically supported by the VDMA (German Mechanical Engineering Industry Association) Industrie 4.0 Toolboxes.

The VDMA Industrie 4.0 Toolboxes are well established and accepted by hundreds of German small and medium-sized enterprises.

VDMA Guideline Industrie 4.0

Your Work Assistance

The status of all Data Sources as well as all Dashboard Panels will be presented in the customizable Power BI.

Here you can soon see some cool BARobot stuff...

These buttons should lead you to sites with different actuators/visualizations/client panels

maybe a picture of the robot?

Global Value Network

Solution Preview

Digital Twin

as Enabler for Sustainability

MBSE as a Cornerstone

of Digital Twin Cobot, EVA

Experience

CAx process chain

of Digital Twin Factory

of a Digital Twin Racing Car